1800 Pieces Per Hour

Most Effective MCB Production On The Market

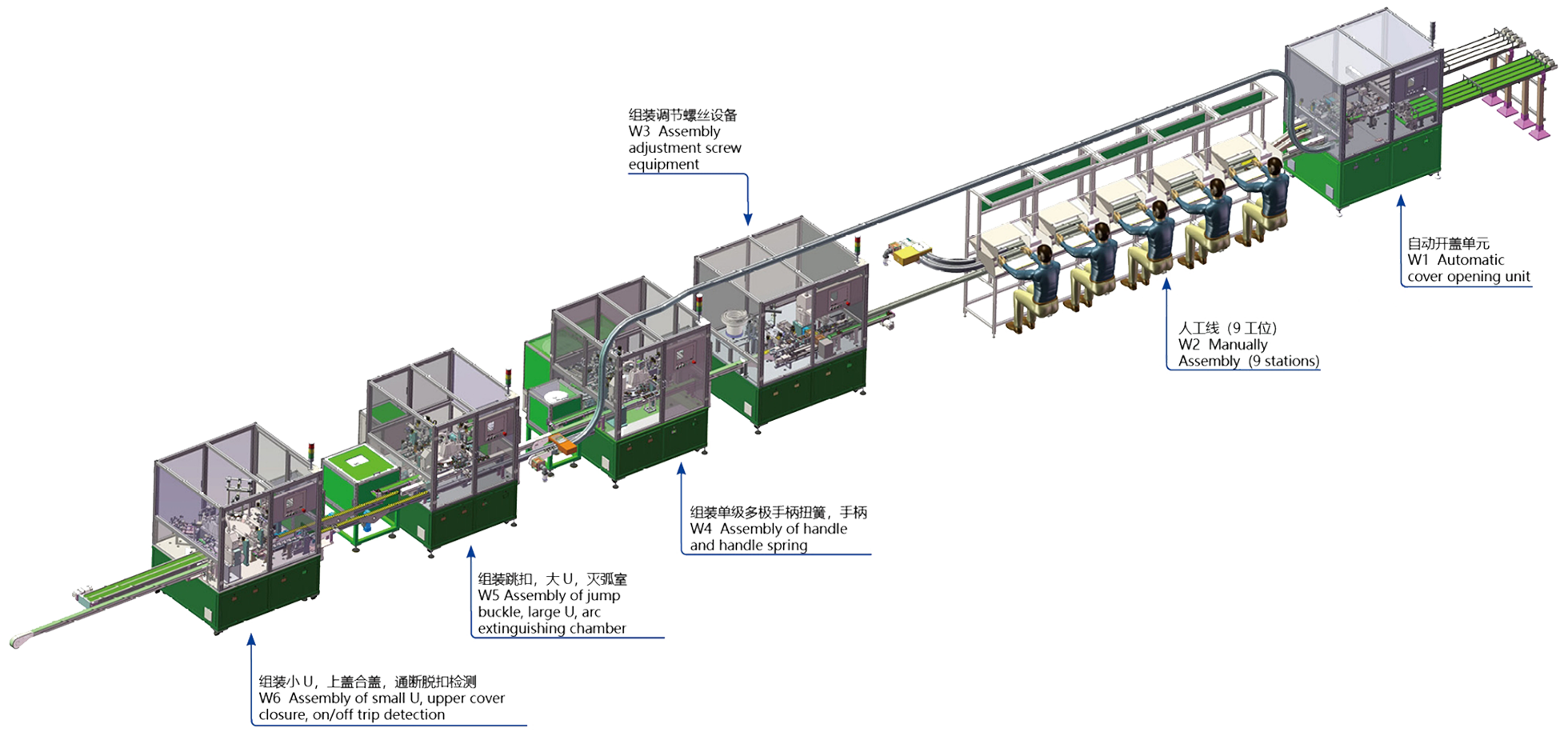

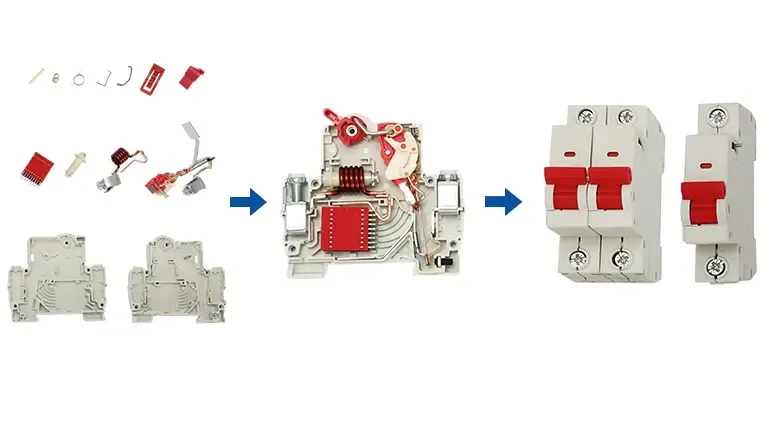

Viiju builds the highly integrated, automated MCB assembly line, greatly reduces manufacturing cost and man risks.

Boost your business with us, join automation with us today.

Boost your business with us, join automation with us today.

Strong Structure

The upper frame adopts 4040 aluminum alloy frame structure and transparent plexiglass.

The lower frame is welded with 4050 square steel with adjustable height and rolling casters

Standout Features

Single Machine Process flow

Put on the belt - automatic group feeding - automatic cover parting- The base flows into the manual assembly line after the cover is opened

-

Lorem ipsum dolor

-

Consetetur sadipscing

-

Sed diam nonumy

Standout Features

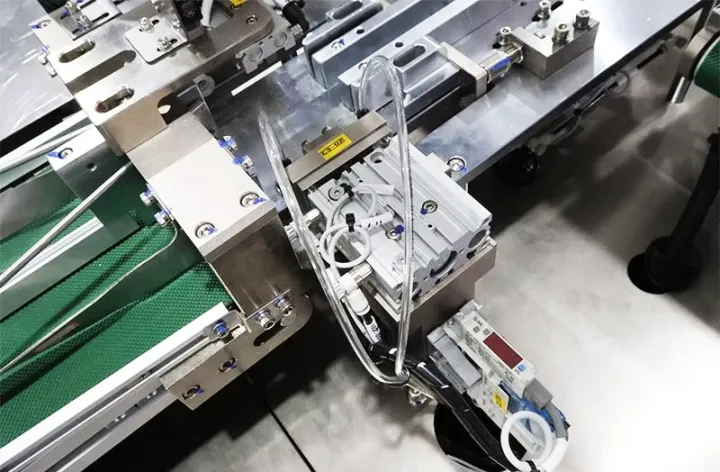

Open Cover Completed

Automatic product distribution

After opening the cover, the top cover flows from above into the next unit The bottom shell flows from below into the next manual assembly unit

After opening the cover, the top cover flows from above into the next unit The bottom shell flows from below into the next manual assembly unit

Standout Features

Technical Specifications

* Standard Configuration

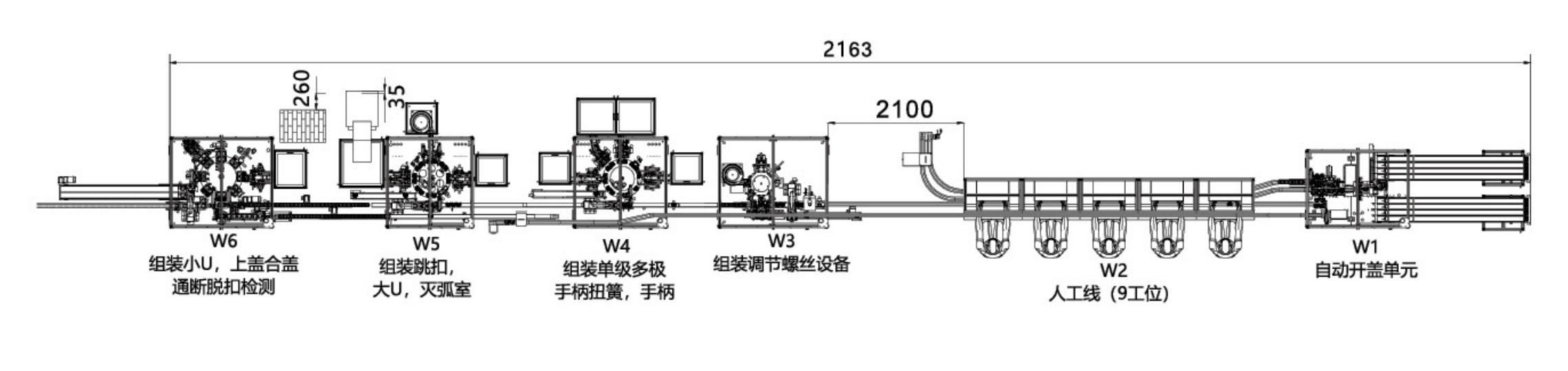

Line Size:

24.3 * 2.4 * 1.9 m

Total Weight:

4170 kg

Voltage:

220 / 380 v

Air Pressure:

0.6 Mpa

Production Efficiency:

2 s/pcs avg.

OEM Availability:

Appearance and interface

Major Components

* Standard Configuration

PLC:

Omron (Japan)

Control Screen:

MCGS (China)

Cylinder:

SMC (Japan)

Major Sensors:

Omron (Japan)

Elec. Motor:

Panasonic (Japan)

Robotics:

Epson / Fanuc (Japan)

Electric Appliance Focused

Viiju has been focused On MCB / MCCB production since its start-up from year 2013.

Technology Strength

Constantly researching on visual algorithm, IoT, sensor and driving, heat / stability management.

Highly experienced

Working with MCB / MCCB manufacturer giants for years, Viiju knows what and how.

Reliable Performance

Major components from reputed world class brands for durable lifetime.

Friendly Start

Before sales, we help to analysis feasibility and efficiency, offering similar projects for reference.

Worry Free Service

After-sale offering on site installation and commissioning. operation / maintenance training.

0$

Free Consult !

A Small Step Saving Big.

- Feeling one of the MCB production process in low efficiency?

- Interested in getting cost for an MCB assembly line?